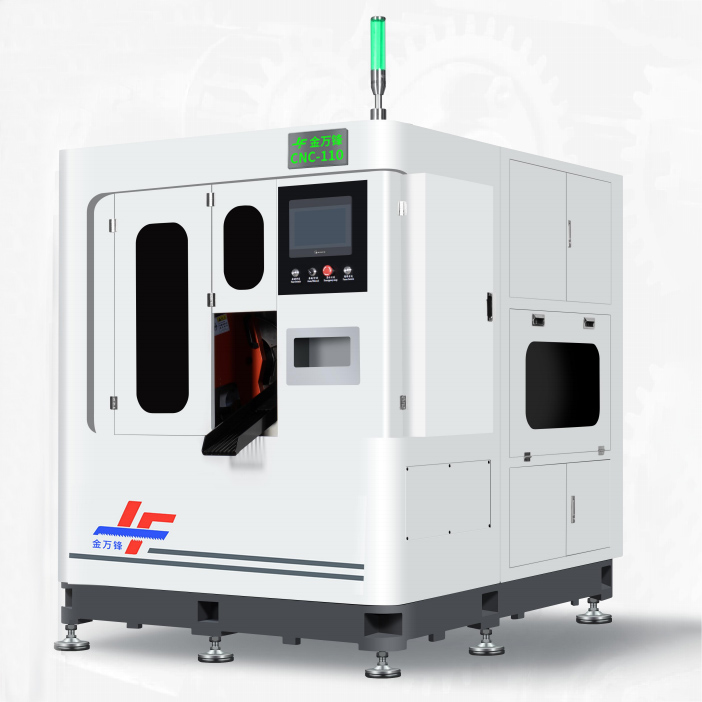

Kanthi otomatis High Speed Aluminium Pipe Stainless Steel Cutting Circular Sawing Machine

Parameter teknis

| Spesifikasi | JF-70B | JF-100B | JF-150B | |

| Spesifikasi Cutting | Babak | Φ10mm-70mm | Φ20mm-100mm | Φ75mm-150mm |

| kothak | 10mm-55mm | 20mm-70mm | 75mm-100mm | |

| Dawane nglereni | 10mm-3000mm | 15mm-3000mm | 15mm-3000mm | |

| Ngarep-ent dawa nglereni | 10mm-100mm | 10mm-100mm | 15mm-100mm | |

| Dawane materi sing ditinggalake (karo poros gambar) | 15-35 | 15-35 | 15-35 | |

| Dawane materi sing ditinggalake (tanpa gambar poros) | 60+ nglereni dawa | 60+ nglereni dawa | 80+ nglereni dawa | |

| Spesifikasi Saw Blade | Jumlah untu | 60,72,80,100,120 | 60,72,80,100,120 | 40,54,60,72,80,100,120 |

| diameteripun Incide * Njaba diameteripun * kekandelan waos | Φ285*Φ32*2.0 | Φ360*Φ40*2.6 | Φ460*Φ40*2.7 | |

| tingkat rotasi poros tengah | 75-190 rpm | 55-150 rpm | 35-105 rpm | |

| struktur feeding | Servo motor + Ball screw + Linear guide rel | |||

| Panganan dawa tetep | Mode nglereni | Pakan horisontal | ||

| kacepetan nglereni | 0-1000mm / min | |||

| Dawane pakan tunggal | 0mm-740mm | |||

| kacepetan dipakani | 20m/min | |||

| Pakan cara clamp | Feed Clamping Hidrolik | |||

| Struktur pakan | Servo motor + Ball screw Linear guide rel | |||

| Motor Spindle (Kw) | 7.5 | 11 | 15 | |

| Motor Spindle (Kw) | 2.25 | 2.25 | 3.75 | |

| Kapasitas tangki hidrolik (L) | 160 | 160 | 160 | |

| Total daya (Kw) | 15 | 18.5 | 27 | |

| Ukuran peralatan: L * W * H (mm) | 260*1955*1865 | 7260*1955*1865 | 7810*1980*1865 | |

| Bobot peralatan (karo rak) (T) | 7.5 | 8 | 8.2 | |

Katrangan Fitur

a. Kothak kumparan dhuwur-daya: Panggunaan pindah tliti dhuwur lan darmabakti kanggo carbide weruh agul-agul desain spindle khusus, kumparan nggunakake bantalan tliti tapered anyar.

b. Servo motor feed: Servo motor karo werni meneng sistem dipakani, bisa kanthi lan cepet ngirim materi kanggo lokasi pas, nambah efficiency karya.

c. Clamps hidrolik lan mencet: Clamps hidrolik lan piranti penet-mudhun nyekeli workpiece kuwat kanggo nyegah geter agul-agul lan nambah akurasi sawing, mulane nambah umur agul-agul.

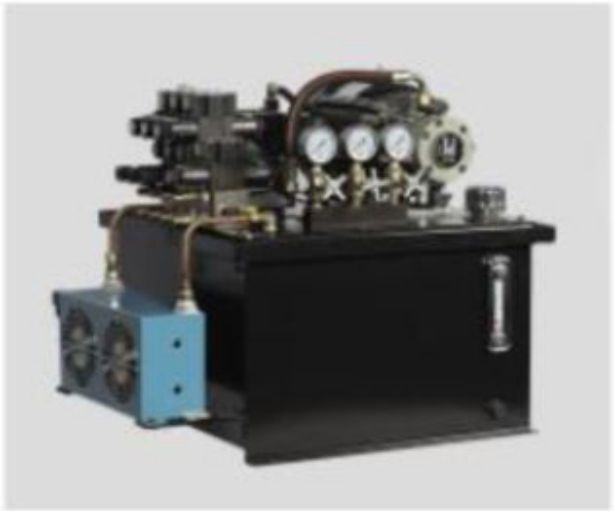

d. Sistem cooling hidrolik: kanggo mesthekake yen suhu lenga hidrolik sistem stabil.

e. Pelumas mikro: ora ana gerakan struktur mekanik piranti pelumasan mikro, nggedhekake seurip rvice.

f. Piranti anti-backlash: anti-backlash nggunakake paling anyar powered kopling tekanan booster kanggo mesthekake yen anti-skidding sawing stabilitas daya, supaya nggunakake pindah poros utama lan loro pindah tansah tanpa longkangan meshing.